See how BKT’s CEO is transforming wastewater into sustainable infrastructure through innovation, technology, and global vision.

In 2025, BKT founder and CEO Dongwoo Kim was recognized for the sixth consecutive year as a Global Sustainable Innovation Leader. To mark this milestone, he gave an in-depth interview to Korea Economic Daily, a leading business publication.

The conversation followed BKT’s evolution from a technology-driven company to a global leader in environmental innovation. Kim discussed BKT’s wastewater technologies, the impact of the Tomorrow Water Project, and the company’s vision for global sustainability.

We now share the full article, which offers a rare glimpse into his strategy, philosophy, and the leadership values that have shaped his journey.

From CPA to Environmental Changemaker

Dongwoo Kim’s background might surprise you. Originally a CPA with no prior experience in the environmental field, he entered the water sector during the Asian Financial Crisis in the late 1990s by acquiring wastewater technologies through M&A.

As an outsider, he initially faced resistance—but his financial insight and long-term vision helped him break into the market and build a sustainable business. Central to that vision was the Tomorrow Water Project (TWP), launched nearly 15 years ago. Its core idea: transform wastewater treatment plants from cost centers into value-generating assets—a concept now being realized through the Co-Flow Campus (CFC) model.

Today, BKT is the only company worldwide to offer all three core technologies needed to process organic waste—biogas production, sludge reduction, and high-strength nitrogen removal.

In 2024, the company achieved KRW 70 billion (approx. USD 52M) in revenue and KRW 10 billion (approx. USD 7.5M) in operating profit. Speaking at Water Korea, Korea’s largest water industry expo, Kim noted:

“Our U.S. operations are performing so well that domestic and overseas revenues are now nearly equal. We are also preparing for an IPO next year.”

Smarter Space, Greater Value

BKT’s strength lies in its fully integrated solution. While many global companies specialize in a single area, BKT combines all three key technologies—offering greater efficiency and cost savings.

“Our solution improves treatment capacity by about 40% while cutting operating costs nearly in half,” Kim explained.

Each technology continues to improve:

- Sludge reduction (DRACO) – A thermal hydrolysis system operating under high heat and pressure, up to 80% more efficient than conventional methods.

- Biogas production (AAD) – Applied at a manure treatment facility in Gimhae, it boosted gas yield by 30% by enhancing microbial health.

- Nitrogen removal (AMX) – Based on anammox bacteria, it earned international recognition at WEFTEC, the world’s largest water industry event, where BKT papers were selected among the Top 50 in 2021 and 2023.

All three core technologies are slated for deployment at the new Daejeon Wastewater Treatment Plant, scheduled for completion in 2028.

Compact Innovation, Global Impact

BKT’s Proteus technology is also drawing global attention. It reduces the spatial footprint of wastewater treatment plants by nearly 50%. During the 2018 upgrade of Seoul’s Jungnang Water Reclamation Center, this allowed land to be repurposed for public spaces like parks and museums.

In Milwaukee, USA, BKT is now building a $13 million demonstration plant using Proteus to enhance sedimentation and stormwater treatment efficiency.

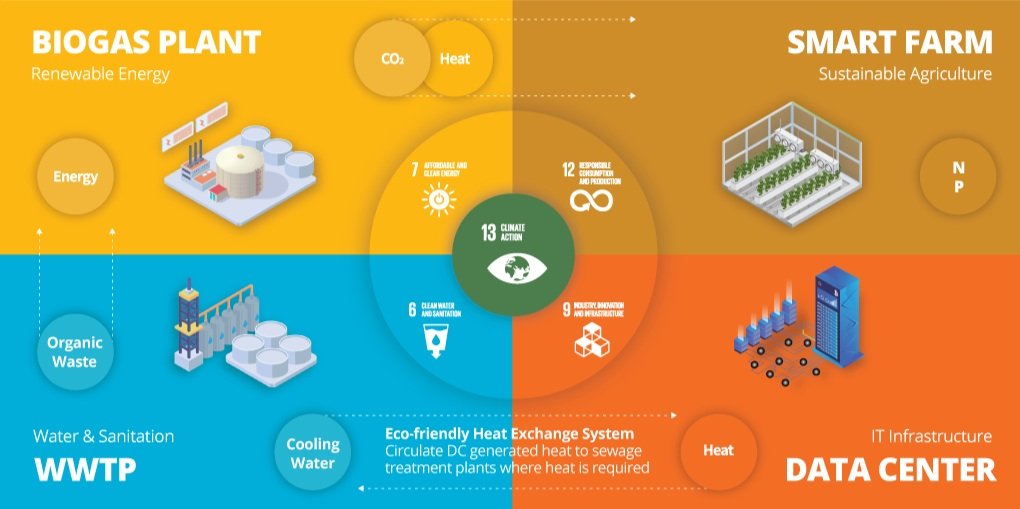

Looking ahead, Kim envisions even more creative uses of treatment plant land—such as hosting data centers that reuse treated water for cooling, or establishing smart farms.

“We’re focused on gathering field data this year for commercial-scale applications,” he said.

Beyond Profit: Redefining Global Leadership

In 2025, Kim was once again named among the Top 100 Global Sustainable Leaders, marking his sixth consecutive year of recognition. This milestone underscores his commitment to redefining wastewater as a driver of sustainability and innovation.

His long-term vision, embodied in the Co-Flow Campus (CFC), is to turn wastewater byproducts into new infrastructure—especially for developing countries.

“We’re researching how AI and 3D printing can make wastewater plants faster and cheaper to build. Our goal is to balance sustainability with profitability—redefining the future of water as a truly global technology company.”

*Source: March 21, 2025| Korea Economic Daily

Interested in learning more about CFC?

Leave a comment