BKT’s IUP integrates DRACO, AAD, and AMX to turn wastewater into energy, reduce emissions, and deliver cost-effective, climate-aligned infrastructure worldwide.

Green Energy Generation,

Minimized Energy Consumption

What is IUP?

BKT’s Integrated Upstream Process (IUP) is a next-generation wastewater and organic waste treatment solution designed to maximize energy recovery and minimize environmental impact. As global cities face rising energy costs, climate pressures, and stricter regulations, IUP offers a breakthrough alternative to conventional treatment systems.

BKT is the only company in the world that has independently developed, validated, and commercialized all core technologies that constitute IUP. These include thermal hydrolysis (DRACO), advanced anaerobic digestion (AAD), and low-energy nitrogen removal (AMX) — each built in-house and optimized for integrated operation.

Why IUP Matters

IUP is more than a combination of technologies—it is the foundational engine of BKT’s Co-Flow Campus (CFC), a new paradigm for future-ready wastewater treatment plants. Unlike legacy systems focused solely on pollutant removal, IUP transforms wastewater facilities into energy-generating hubs that contribute to urban sustainability and climate goals.

Through IUP, BKT enables:

- Carbon neutrality – by reducing emissions from sludge and untreated organic waste

- Energy self-sufficiency – by maximizing biogas production

- Circular resource use – by recovering water, energy, and nutrients

IUP is BKT’s response to the urgent call for scalable, cost-effective, and climate-aligned infrastructure.

The Technologies Behind IUP

These three technologies work seamlessly within the IUP framework:

- DRACO (Thermal Hydrolysis) – Improves sludge biodegradability and boosts biogas yields by up to 50%. Post-digestion, it reduces sludge cake volume by 75%, significantly lowering disposal costs.

- AAD (Advanced Anaerobic Digestion) – Provides enhanced stability for complex organic waste streams, extends sludge retention time, and increases gas productivity.

- AMX (Anammox) – Enables biological nitrogen removal with over 60% less aeration energy and 99% less chemical usage. Proven effective for digestate from mixed waste streams such as livestock manure and food waste.

Each of these technologies has been commercially deployed and field-tested, and will be explored further in upcoming articles.

Core Technologies of IUP

IUP is an optimized and well-balanced integrated solution for digestion and co-digestion applications.

With advanced real-time monitoring and control systems, it ensures efficient and easy operation under optimal conditions at all times.

Real Projects, Real Results

IUP is not a concept—it’s a reality. In South Korea, IUP has been successfully adopted in major infrastructure projects, including:

Daegu City Integrated Biogas Demonstration Facility

AAD and AMX applied to treat 20 tons/day of mixed waste. Achieved 30% more biogas, 73.6% energy savings in sidestream treatment, and 100% energy self-sufficiency—a model for energy-positive facilities.

Busan Noksan WWTP

First site to commercialize AMX. The plant achieved a 60% reduction in energy costs and saved over KRW 1.5 billion (approx. USD $1.1 million) in annual operating expenses.

Miryang & Gimhae Biogas Plants

AAD-based digestion of 100–200 tons/day of mixed organic waste demonstrated 30% more gas yield than the design target.

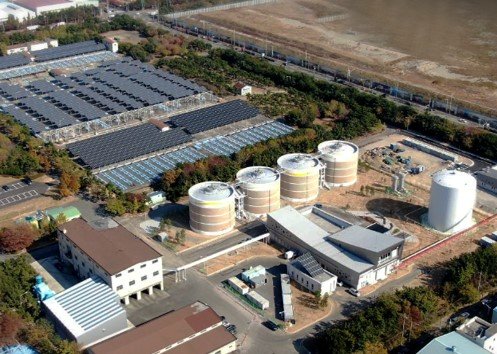

Seohae Green Sludge Reduction Facility

In the Seohae project, DRACO is expected to maximize energy efficiency and reduce outsourced sludge treatment by over 80%, significantly lowering operational costs.

Daejeon WWTP Modernization Project (Completion: 2028)

Designed to treat 495 tons of sludge per day, the project integrates DRACO for enhanced biogas production, AAD for stable digestion, and AMX for cost-effective nitrogen removal.

These successes validate IUP as a cost-effective, scalable solution for both public and private sector wastewater infrastructure.

A Global Vision for a Carbon-Neutral Future

BKT is leveraging the Integrated Upstream Process (IUP) as a strategic export solution to support global carbon neutrality initiatives. With new regulations such as Korea’s “Biogas Promotion Act” driving demand for integrated biogas systems, BKT is aligning with the international push for decarbonization.

By partnering with global climate companies such as ReCarbon (for syngas conversion and low-carbon fuel production) and Capture6 (for direct air carbon capture and carbon credit generation), BKT is unlocking new value from both biogas and CO₂ emissions.

BKT is also actively participating in international carbon reduction projects, including a Clean Development Mechanism (CDM) initiative in Uzbekistan. This project demonstrates BKT’s commitment to delivering real climate solutions in emerging markets—not only through technology, but also through its operational expertise.

As a verified solution provider, BKT is currently preparing CDM project registrations and accelerating IUP deployment across Southeast Asia, Central Asia, and North America.

IUP is more than a treatment process—it’s a model for sustainable transformation. BKT is proving that even wastewater can power a cleaner, more resilient future.

Want to learn more about IUP?

Leave a comment